Control System Migration Services

Legacy PLC, Motion, Drives & HMI

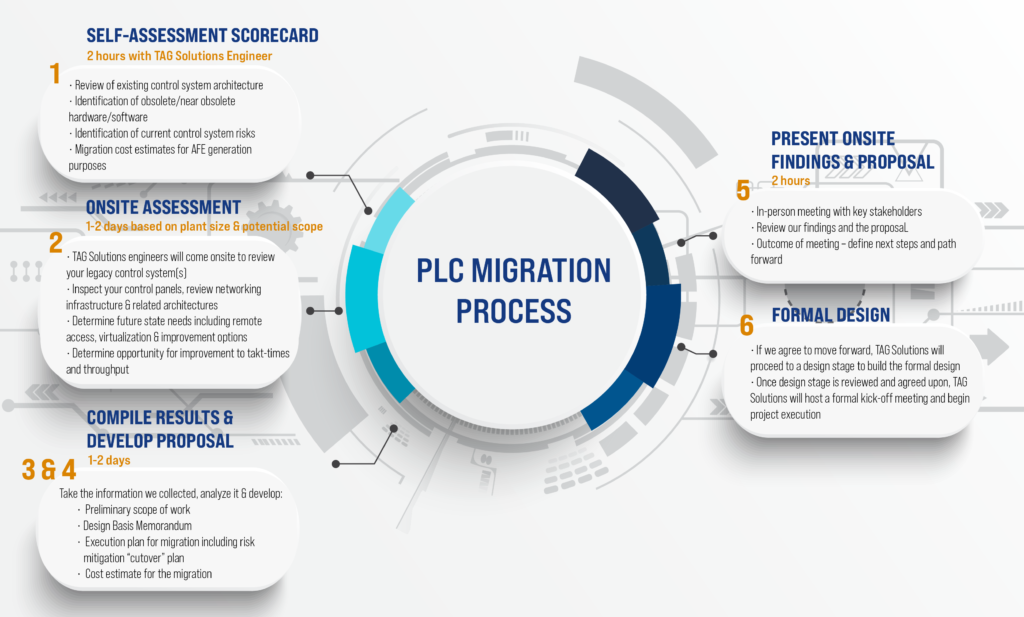

Managing the lifecycle of your control system can be a daunting risk. Migrating your existing control systems mitigates expensive and extensive downtime. A poorly executed upgrade presents the same risk. Discover how our Migration Team can solve these lifecycle challenges with the experience to execute on schedule.

Eliminate Risk Associated with Obsolete PLC Systems

Migrations: Made Simple

Series 90-70 to RX3i Conversion Rack

Step 1: Existing Series 90-70

Step 2: Remove field terminals

Step 3: Remove Series 90-70

Step 4: Install RX3i conversion rack

Step 5: Install Series 90-70 field terminals

Step 6: Close access door and secure

Step 7: Exchange completed

Conversion rack side view

Top Reasons & Benefits to Migrate

Reduce Downtime

Obsolete hardware can cause downtime including:

- Security risks

- Lack of spare parts

- Time consuming troubleshooting

- Unstable connections

- Software that is difficult to navigate

Improve Throughput

Improve throughput by decreasing cycle times associated with equipment that is slower in performance

Improve Quality

Improve quality metrics and reduce scrap reduction rates/costs

Reduce Lifecycle Costs

Old equipment gets more expensive to maintain over time.

Modernize OT Network

Upgrade and modernize your OT

Networking including legacy field devices that are not ethernet capable

The TAG Solutions Difference

Our Approach to Migrations

The TAG Solutions Migration Team has developed a proven strategy that will allow you to quickly and easily migrate from Series 90 and RX7i controllers and Series 90 I/O to an Integrated Modern Control System, while maintaining the existing field wiring and physical footprint in your control cabinet.

Video series

90-30 Migration to RX3i

Packaging Manufacturer

Packaging Manufacturer

Choosing UR for their open platform gave ClearPack the flexibility to program the application themselves.

Furniture Manufacturer

Furniture Manufacturer

Becker Romania increases productivity by automating glue dispensing and assembly processes with UR10 Robots.

Global Beauty Company

Global Beauty Company

Universal Robots Delivers Half a Million Dollars in Annual Savings at Coty Cosmetics.

Case Studies

Streamline your Palletizing and Machine Tending Applications with Collaborative Automation

MACHINE TENDING CASE STUDIES

Precision Machining Company

Precision Machining Company

The UR ActiNAv solution boosts competiveness, empowers workers and extends lifespan of legacy equipment for PrecisionForm.

Fire Equipment Manufacturer

Fire Equipment Manufacturer

Vision-guided collaborative robots deliver fast ROI for Task Force Tips. Their investment in three UR robots paid for itself in 34 days!

Lighting Fixture Manufacturer

Lighting Fixture Manufacturer

Temar’s investment made the company a more competitive manufacturer and an attractive employer–the mundane tasks are now performed by cobots.