Operators Built for Mundane Tasks

Maximize Efficiency, Increase Quality, Optimize Production and Relieve Your Workers from Repetitive Tasks

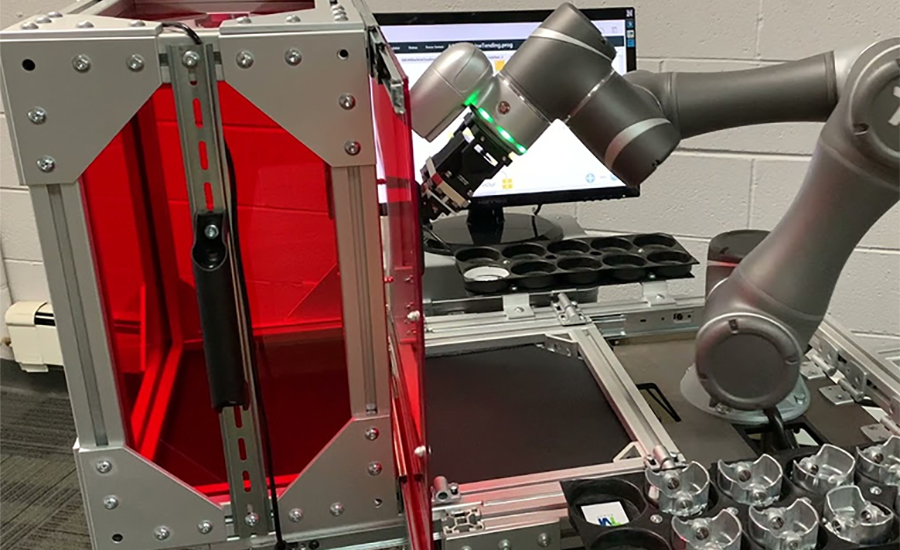

Cobots never get sick or tired; they deliver consistent, high quality results shift after shift. Machine tending and palletizing, the most common jobs in manufacturing, can now be automated easily. Operators can focus on more valuable tasks. This productivity increase is even more valuable with skilled operators, such as CNC machinists and box loaders.

While cobots are not suitable for primary food handling, they are being used widely for handling, packaging and palletizing of packaged foods and beverages.

THE SIMPLE SOLUTION

The Advantages of Collaborative Automation

FLEXIBILITY

Cobot robot arms are easily programmed and redeployed and can be mounted on carts for mobility. Solving both your palletizing and machine tending needs.

PRODUCTIVITY

Add new functionality without costly changes to production lines. Meet competitive demands for faster output, even in processes not typically suited for automation.

CONSISTENCY

Increase quality and consistency in repetitive tasks where human workers struggle. Cobots can work non-stop while operators focus on higher-value tasks.

ROI

See your ROI in a matter of months! The added value cobots bring to your production will increase efficiency, production and your bottom line.

GET STARTED BUILDING YOUR COLLABORATIVE SOLUTIONS

Help us to better understand your needs by answering these few questions. An Applications Engineer will contact you within 48 hours.

PALLETIZING CASE STUDIES

Packaging Manufacturer

Packaging Manufacturer

Choosing UR for their open platform gave ClearPack the flexibility to program the application themselves.

Furniture Manufacturer

Furniture Manufacturer

Becker Romania increases productivity by automating glue dispensing and assembly processes with UR10 Robots.

Global Beauty Company

Global Beauty Company

Universal Robots Delivers Half a Million Dollars in Annual Savings at Coty Cosmetics.

Case Studies

Streamline your Palletizing and Machine Tending Applications with Collaborative Automation

MACHINE TENDING CASE STUDIES

Precision Machining Company

Precision Machining Company

The UR ActiNAv solution boosts competiveness, empowers workers and extends lifespan of legacy equipment for PrecisionForm.

Fire Equipment Manufacturer

Fire Equipment Manufacturer

Vision-guided collaborative robots deliver fast ROI for Task Force Tips. Their investment in three UR robots paid for itself in 34 days!

Lighting Fixture Manufacturer

Lighting Fixture Manufacturer

Temar’s investment made the company a more competitive manufacturer and an attractive employer–the mundane tasks are now performed by cobots.

Customer Success

Our Customers Say it Best

Ops ManagerMetals & Machining

CEOElectronics Manufacturer