Pharmaceutical Manufacturer Automates their IV Bag Production Line

UR3 robot fill IV bags on a production line increasing safety, accuracy and repeatability

Automation technologies help in improving the efficiency of the pharmaceutical development and production by streamlining the processes. The technologies enhance efficiency as robots can easily perform repetitive tasks such as filling and packing at high accuracy and speed compared to human workers. They are also highly accurate and eliminate the possibility of human errors in the weighing, blending and packaging of pharmaceutical products.

Story

This Carolina-based manufacturer is an industry leader in pharmaceutical product development. They are also experts in the blow-fill-seal (BFS) technology and have an exceptional track record of delivering billions of doses without a single interruption.

Challenge

The company wanted to use automation to improve their IV bags production, without compromising quality and consistency. By automating the production line they sought to improve the quality of the finished product, but also improve accuracy and repeatability while reducing errors and material waste. Automating these menial but vital tasks would free up their employees to perform more valuable, engaging work and provide flexibility when dealing with labor availability challenges.

“Using manual labor for the delicate task of filling IV bags can produce inconsistent results and create safety issues for the operator because they get tired and towards the end of the day mistakes can be made, whereas with a robot, you can always count on a consistent output,” stated Amir Furhang, Engineer Manager at CIMTEC.

Solution

CIMTEC designed a machine tending solution that not only solved their challenges, but increased their production and accuracy. While the customer had experience with traditional automation, deploying a machine tending solution was a new experience.

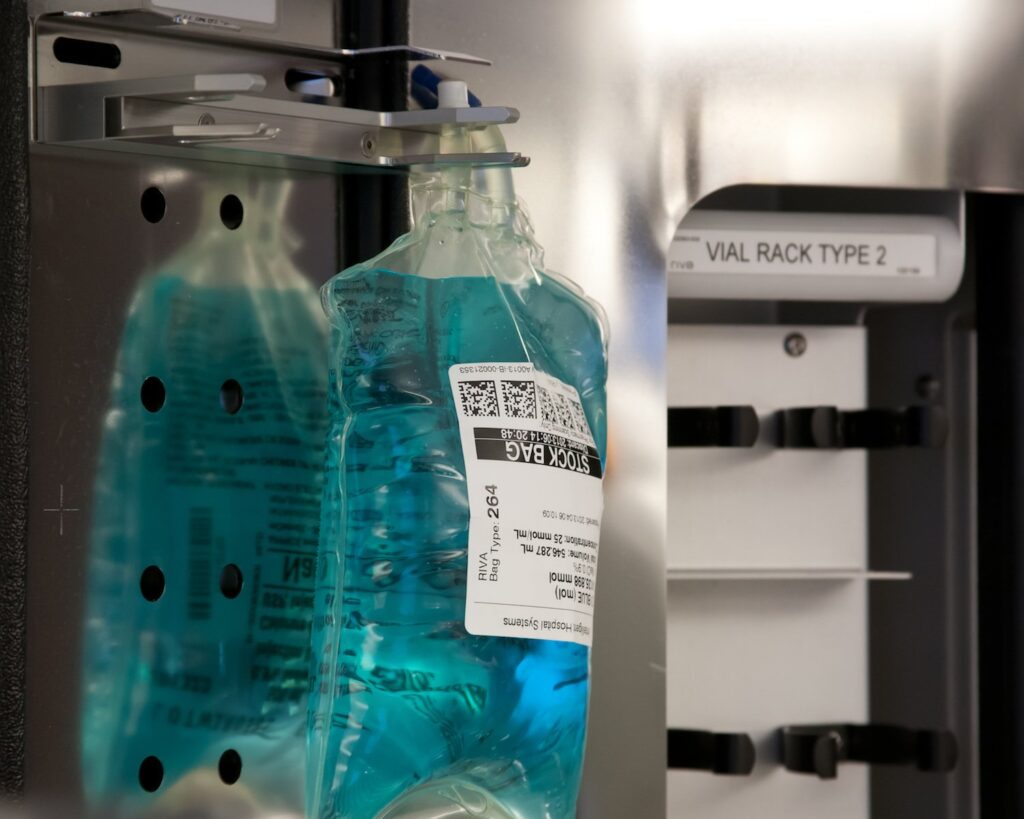

Using a UR3 robot, a custom bracket was designed to hold the needle then an air pressured hose was connected to the needle. The robot extracts the solution from a vessel and methodically fills the IV bags. A simple, but valuable solution ensuring product quality, safety, and freeing their operators up to do more valuable tasks.