PRECISIONFORM INC.

ACTINAV EXTENDS THE LIFESPAN OF LEGACY EQUIPMENT AT PRECISIONFORM, IMPROVES WORKER EMPOWERMENT, AND IMPROVES COMPETITIVENESS.

Story

The responsibility of picking parts out of deep bins and placing them onto a CNC machine was given to PrecisionForm, a market leader in small bespoke metal parts, using an automated system. ActiNav, a flexible machine loading system from Universal Robots, was implemented by the business to increase productivity, address labor shortages, empower employees, and prolong the life of more-expensive machinery.

Challenge

What is the biggest challenge in automating a task? How to give the robot the part. PrecisionForm soon came to this conclusion when automating their debut project, which involved using a robot to select piston rings and set them on a micrometer for inspection. The rings were batch manufactured and shipped in large bins with other parts at the contract manufacturer in Pennsylvania. An operator had to first arrange them on a tray in a grid pattern so that the cobot could pick them up.

“50-75% of our time spent getting that application up and running was figuring out how the robot would pick the parts,” says Alex Corckran, President and CEO of PrecisionForm. “Having an operator lay out parts for the cobot was still faster than doing the whole inspection process manually – but wouldn’t it be nice if the cobot could just pick directly from the bin and bypass this whole step?”

For their upcoming project, taking components out of bins for CNC milling, PrecisionForm started looking into bin picking options. To find out if the parts could be taken out of bins, the business contacted several vendors and sent them sample parts. “The answers were always, ‘Yes: but…’ and the “buts” were never acceptable to us,” says Corckran, recalling how some systems had trouble with parts that were certain colors, others had issues with flat parts, while some systems required the vendor’s engineer to come out and handle the changeover from one part to the next.

“We have 50 to 100 parts that we touch on a weekly basis for inspection or secondary processes,” says the PrecisionForm CEO. “The vast majority of those parts are not high enough quantities to justify having a fully automated solution that we can’t easily switch between parts.”

Using a bowl feeder for part presentation wasn’t a viable option, explains Corckran. “Bowl feeders are effective when you have very high volumes and you have the right part for the job. For other parts, when you have lower volumes, the changeover between one part to the next on a bowl feeder is either impossible, or just takes too long to make it effective. In many cases, it’s just easier to have a person do that work rather than switch over the automation process.”

Solution

Corckran was dubious when Universal Robots (UR) and UR distributor Applied Controls suggested a test of the ActiNav solution to PrecisionForm: “We figured it was going to be the same as all the other bin-picking solutions, where we send them a part and weeks later they send us a ‘But.’” Nevertheless, PrecisionForm sent the ActiNav team sample parts along with CAD drawings and 3D models. “We were actually shocked,” says Corckran. “We sent them two parts, including one with a very small, flat surface that never sits in the bin properly and within 24 hours they had sent us three demo videos of ActiNav actually picking the parts out of a bin.”

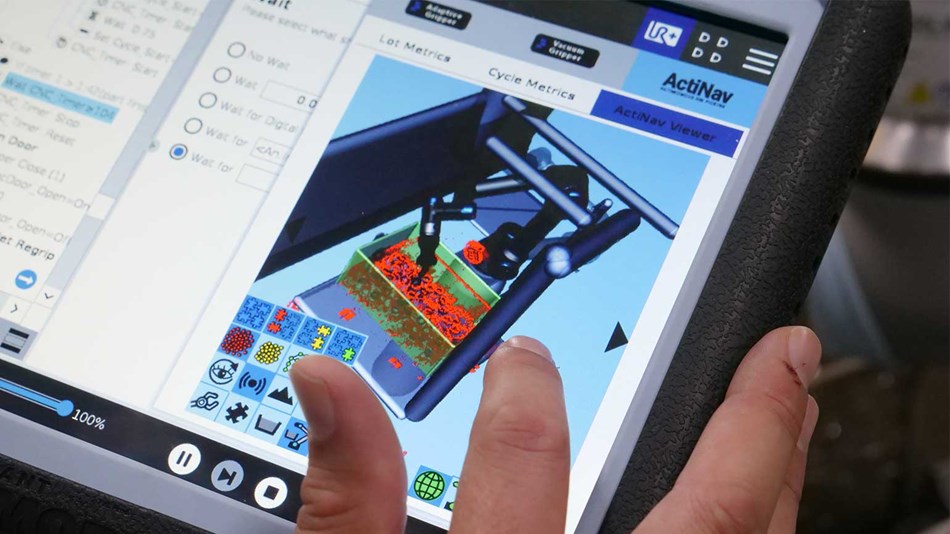

A versatile and user-friendly machine loading solution is produced when a UR cobot is coupled with an award-winning ActiNav Machine Loading kit. The kit’s hardware and software seamlessly work with the cobot to analyse visual data, plan collision-free movements, and manage the robot on its own in real time.

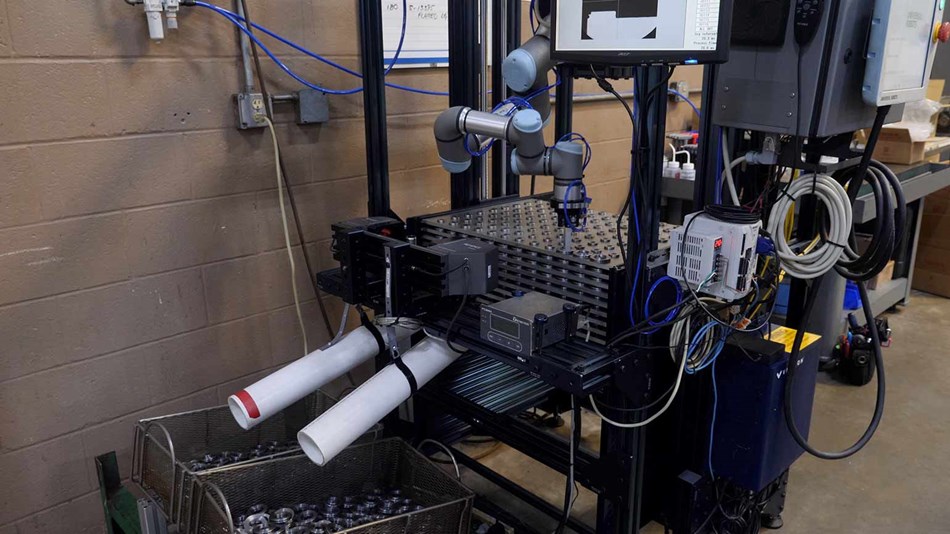

Simple Automation Choice

The UR3 cobot from Universal Robots conducts the initial piston ring inspection process, and the UR5 loads and unloads components in a brake press. PrecisionForm already had both of these cobots. PrecisionForm chose to purchase a second UR5 equipped with the ActiNav solution and deploy it for a very straightforward, low-hanging fruit task: picking firearm parts out of a bin and into a CNC machine. This decision was made based on PrecisionForm’s positive experiences with Universal Robots’ cobots and the impressive results of the initial bin picking samples. The task is ideal for automation because it has a cycle time of 90 seconds and only needs one full-time operator to tend to it.

The ActiNav system took maybe a day to set up and deploy, says Dan Vazquez, industrial automation engineer at PrecisionForm: “The first step is to define the environment and calibrate the sensors, which is very straightforward. You drag the robot arm to points where you want to place environment objects and once you define those points, the robot will autonomously plan its paths based on that information.” Next, Vazquez simply fed the cobot a CAD file of the part to be picked. “ActiNav will be able to identify the part within the bin, as well as its position on the end effector while it also autonomously plans further movements,” he explains, adding that PrecisionForm implemented two re-grip stations in the cycle where parts are placed to optimize cycle time and give the cobot the correct angle to pick the part for final placement.

ACTINAV EMPOWERS WORKERS AND OVERCOMES LABOR PROBLEMS

PrecisionForm can’t be competitive at an international level from Lititz, Pennsylvania with one operator running one machine at a time, says Corckran: “We have a whole lot of very skilled workers. A lot of these very repetitive tasks are intermittent, so we often find ourselves having to take a highly-skilled person and put them on a very repetitive task, and that’s not great for morale, and it’s not cost-effective either.”

After the ActiNav deployment, operators can operate three or four machines simultaneously, allowing the business to maintain its competitiveness and get beyond difficulties related to sporadic needs for temporary personnel. In Corckran’s experience, it can be difficult to locate “excellent, qualified personnel to show up on a regular basis when you need them” when temporary labor is needed to do irregular duties. That issue is resolved by ActiNav.

INSPECTION WITH ACTINAV GIVES LEGACY EQUIPMENT ANOTHER 10 YEARS ON THE FLOOR

PrecisionForm’s manufacturing facility combines the “latest-and-greatest CNC equipment” with “30-year old equipment that’s still very effective at its job,” says Corckran. The ability to implement ActiNav on older equipment doesn’t just have the obvious ROI of replacing an operator or allowing a single operator to operate four machines, explains Corckran, it allows companies to rethink whether or not that piece of equipment needs to be replaced: “For example, we have some machines that produce very high-volume parts, in the millions a year. At some point, those machines wear out, and they stop producing 100 percent, or 99.999 percent good parts. In the old reality, we would have to replace that machine to stay competitive,” he says and continues: “However, if we can implement ActiNav next to that machine and inspect out the one percent of bad parts, we’ve just taken a million dollar piece of equipment, added a very inexpensive solution to it, and potentially gotten another ten years out of it.”

PrecisionForm manufactures parts with incredibly precise tolerances, and customers carefully inspect each component. The operators pause once per hour for ten to fifteen minutes and thoroughly inspect the part and the die in order to maintain the company’s outdated machinery producing at the level clients expect. As much as 15 to 20 percent of daily production was lost, but thanks to ActiNav, we can now make up for it, says Corckran, who also mentions that PrecisionForm plans to use an additional ActiNav system on its first piston ring inspection application in the future, doing away with the need for manually loaded trays.